A rubber compound is produced by adding specific chemicals to raw rubber material in order to improve and alter the characteristics of the rubber for the desired use. Selecting the correct rubber compound is vitally important for any application in a...

A rubber compound is produced by adding specific chemicals to raw rubber material in order to improve and alter the characteristics of the rubber for the desired use. Selecting the correct rubber compound is vitally important for any application in any industry, and the best way to do this is to select which rubber compound properties are most important.

In this post, we’re looking at some of the different properties of rubber compounds and how you can choose the right rubber compound for your applications.

Rubber Compound Properties

Every application of rubber compounds is different, and each requires different properties. However, natural rubber is the preferred choice for many applications as it often provides the best dynamic properties overall. In addition, additives can be used to improve characteristics such as resistance to ageing.

Synthetic rubbers can also be mixed with natural rubber to create hybrid rubber compounds, and these can benefit from the shared characteristics of each type of compound.

Some of the most important rubber compound properties include:

- Hardness – you can measure rubber hardness using the Shore hardness scale.

- Temperature resistance – resistance to temperature extremes can be very important for certain applications.

- Tensile strength – this refers to the amount of force needed to break the rubber by pulling it apart.

- Elongation – when tensile force is applied, the elongation is how far the rubber will stretch, measured in the percentage change of length before breaking.

- Abrasion – if the rubber compound will be used for an application that has a lot of abrasion, like rubbing or scratching against the surface, it must be able to stand up to that abrasion.

- Flexibility – this can be an important rubber compound property, as flexibility might be a necessity or could hinder the component’s functionality.

- Resistance to different conditions or materials – heat, light, oxidising, ozone, wear and tear, chemicals, acids and water, among others, are all things that are key to choosing the right rubber compound.

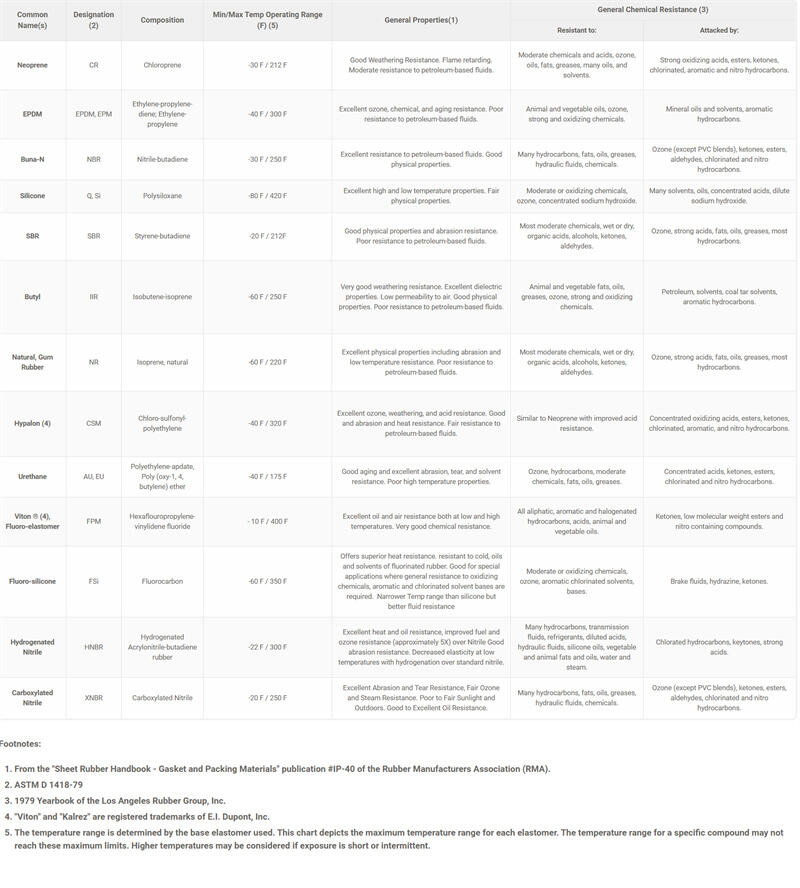

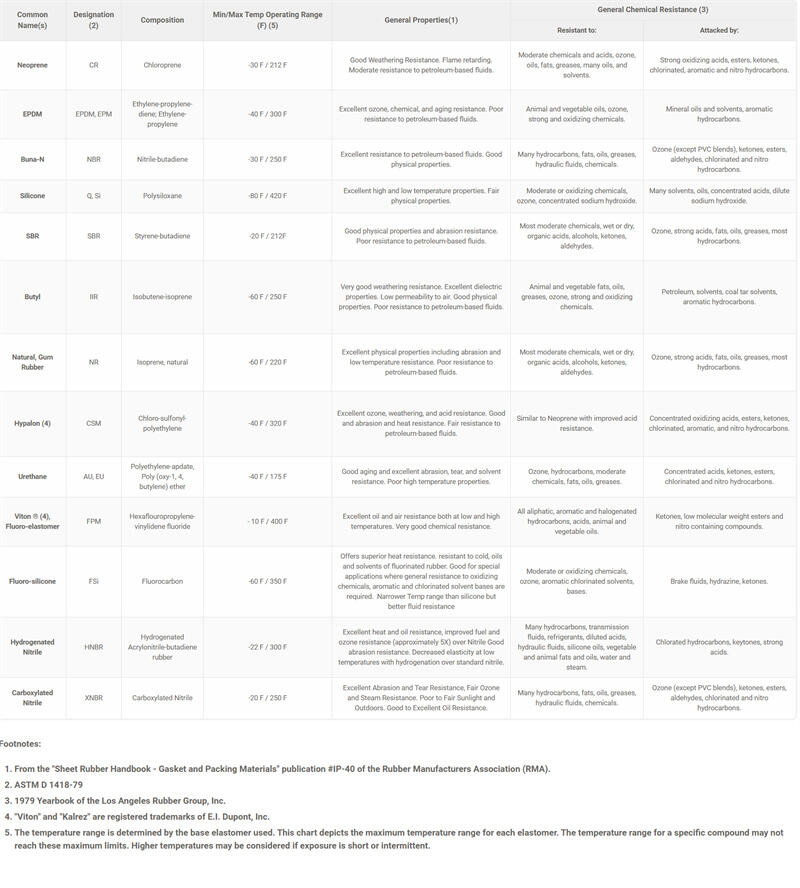

The following table can be used as a guide to help you select the preferred rubber compound for a particular application.